TYPES OF TRAILERS:

there are two main types of trailers single axle and tandom axle trailers. there are also triple axle trailer which arnt as commen as they are only used on really hevay boats. then there are roller style trailers which are the most commen where as skid trailers arnt as commen because they have to be samuged to take the bost off the trailer and to retrive the boat. with the roller trailer you dont have to put it as far under the water as you do with a skid trailer because for easy launching with a skid trailer the trailer has to be under the water alot more then a roller trailer.

tandom trailer with rollers

single axle trailer with skids

TRAILER MATERIALS:

there are two main types of trailer materials galvanized steel and aluminium. there is also steel trailers but there arnt as commen as there rust alot easier. galvanized steel is the most strongest materal to use when making a trailer and has very good protection againest salt water. aluminium trailers are made of high quality aluminium which is still strong but they weigh alot less than galvamized steel trailers. aluminium trailer arnt as durable as galvanized steel trailers however aluminim trailers have alot more protection than steel trailers

galvanized steel

aluminium

steel

Overal dimentions and regulations:

If you are towing a boat you can tow a trailer that can be 2.5m wide, up to 4.25m high when the boat is sitting on the trailer, and 11.5m long, however the trailer and truck must not be more than 20 meters all up.

when towing a trailer the maxim weight you are aloud to tow is 3.5 tonne (3500kgs). if the load on a trailer is more then 2 tonne(2000kgs) you have to have a braking system.

Braking systems:

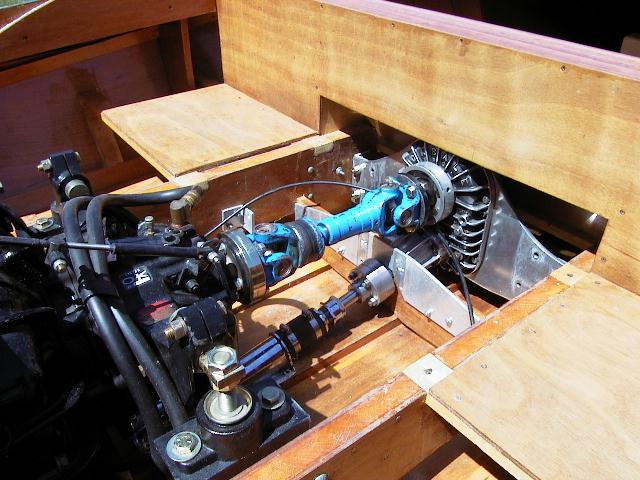

The main and relly only braking system when towing a trailer is hydrolic braking. hydrolic braking comes in to forms disk and drum brakes. there are to main ways of controling them. you can have them hooked up to your braking system so when you put your foot on the brakes it also brakes on the trailer aswell. You can also have the hydrolic coupling braking system which provents surging with the trailer. so when you put your foot on the brakes theres a hydrolic in the coupling and then this acdivates the brakes on the trailer.

hydrolic coupling

Types of suspension:

There are two types of suspensin there is leaf spring (most comen) and coil springs. leaf suspension is the most comen type of suspension and been around for 100's of years. leaf suspension sprends the weight over 4 equal points on a chasie. they are very easy to set up as its reely only a few bolts in the middle and at each end of the leaf spring. however they are alot more difficult to adjust. coil spring suspension is alot harder to set on trailer as you need to set up torsion bars which make them a pain. they are also very bouncey on a light trailer.

Leaf suspension

Coil suspention

Winches:

trailers are used to haul goods that are very heavy in weight or huge is size. Trailer winches are made to make the loading and un loading of trailes smoother and easier. If you where loading and un loading boats from there trailers with winches it would be come very hard and the risk of damage will incress o shit load.

The advantage of having an electric winch is that there is hardly any phisicaly strenth need to opperate. where as with a manuel winch you will have to be quite fit to winch in a big boat.

manaul winch

eletric winch

Hubs and Bearings.

Most new bearing have bearing protectors that are called bearing buddys. when your driving down the road your bearings on a trailer heat up. when you stick them in fresh or salt water they cool down and shrink. with old bearings when this use to happen they sucked the water into the bearing and this would could it to rust and damage the bearing. now with the new bearing buddy it is a sealed metal chamber thats attacers to the bearing. They are packed with greass and has a spring in it is when it go's in water and shrinks insteed of salt water been sucked in it suks greass in. this inrcesses the life in a bearing alot.

bearings without bearing buddys

bearing buddy

Your hubs on traliers are normaly inderpendent hubs. witch means they are not attached with one another.

your hubs are also for bracking. this is for disk and drum breaks. drum breaks are old and are becoming outdated noe disk breaks are coming in.

Lights

LED lights last alot longer than ordinary bulbs an LED bulb can last for over 10,000 hours while remaining with the same quality of light. The actual quality of light is better than an ordinary bulb and less energy is lost in heat. trailer lights are expossed to water and need to be able to enjor alot.

ordinary trailer lights

LED trailer lights

Couplings

Most trailers have ball and socket coupling systems. These are fine for a small trailers. anything over about 4.5 tonn you will need a heavey duty coupling system. most cars and 4X4's these days have the ball for the ball and socket coupling system.

tandom trailer with rollers

tandom trailer with rollers hydrolic coupling

hydrolic coupling Coil suspention

Coil suspention eletric winch

eletric winch